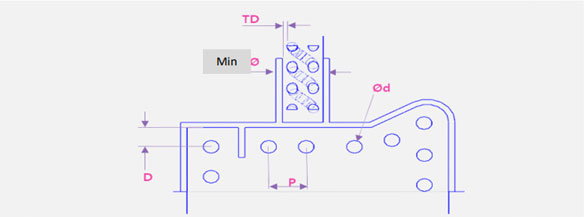

DMLS Design Guide

Cooling channel size(mm)

[∅d] Hole

Minimum ∅d 3.0 ~

(∅d 1.5~/TD min. 1.5~)

[D] Distance

i.5 to 2 x ∅d

[P] Pitch

2-3 x ∅d(3.0~)

Bracketed dimensions are applicable according to mold structure conditions

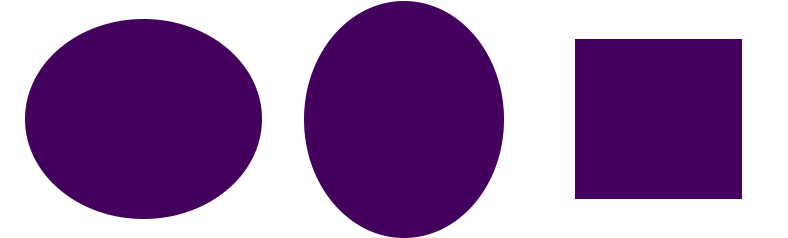

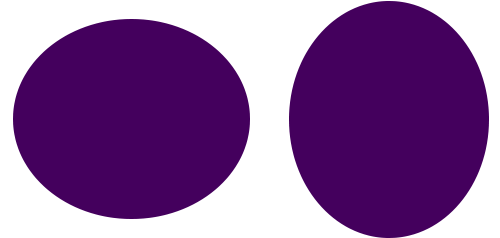

Cooling channel Geometry

Recommended geometry

Circle/Oval (recommended)

Other (Bad)

Rectangle/Pentagon (apply conditions)

Other (Bad)

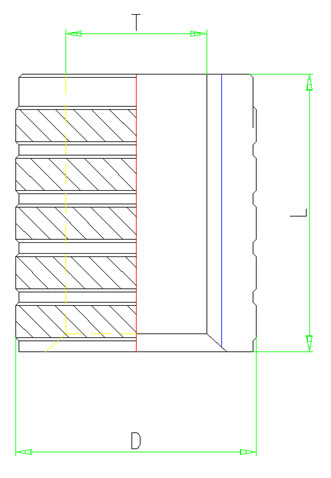

Mold-In Insert Spec / Boss Design Guide

Design Guide

Molded-In Insert specifications.

| T(M x Pitch) | D | L |

|---|---|---|

|

M2 x 0.4 |

∅3.0 / ∅3.5 |

Optional |

|

M3 x 0.5 |

∅4.5 / ∅5.0 |

|

|

M4 x 0.7 |

∅6 |

|

|

M5 x 0.8 |

∅8.0 |

|

|

M6 x 1.0 |

∅8.0 |

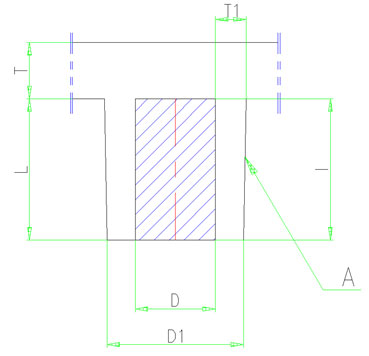

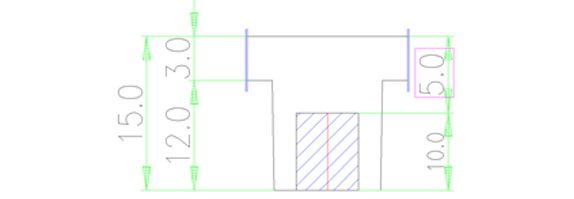

Boss Design Guide

EX

Reference for Insert length selection.