Why M3 PARTNERS?

Metal 3D printing or internal complex channels and CNC machining to the outer surface achieving precision tolerance.

Implementing optimally designed heat control process parts.

Achieve conformal cooling channels for injection mold enabling faster cooling time and higher productivity.

Perform Metal 3D printing and 5-axis CNC machining at the same time in one equipment.

Two types of materials applicable to the same part.

Cladding applicable for the repair of parts.

Various material options such as aluminum, Inconel, stainless steel, and tooling steel.

Many years of experience making highly complex geometries parts for the overseas customers around the world.

3DM – DMLS(Direct Metal Laser Sintering)

For the complex parts that are not achievable by conventional CNC machining, M3 Partners can make it feasible by metal 3D printing and post-CNC machining combined for the design of highly complex geometries. As a forerunner in the metal 3D printing industry in Korea, M3 Partners is equipped with premium 3D printers in the world and has been accumulating valuable manufacturing know-how in this technology such as implementing conformal cooling channels for die casting and injection molding cores and sprue bushes.

DMLS Material

AISi10Mg SUS 316L, Inconel™ 718, Maraging Steel MS1

Flatform size

[M290] - 250 x 250 x 325 mm

Finish

Sanding, Heat Treatment

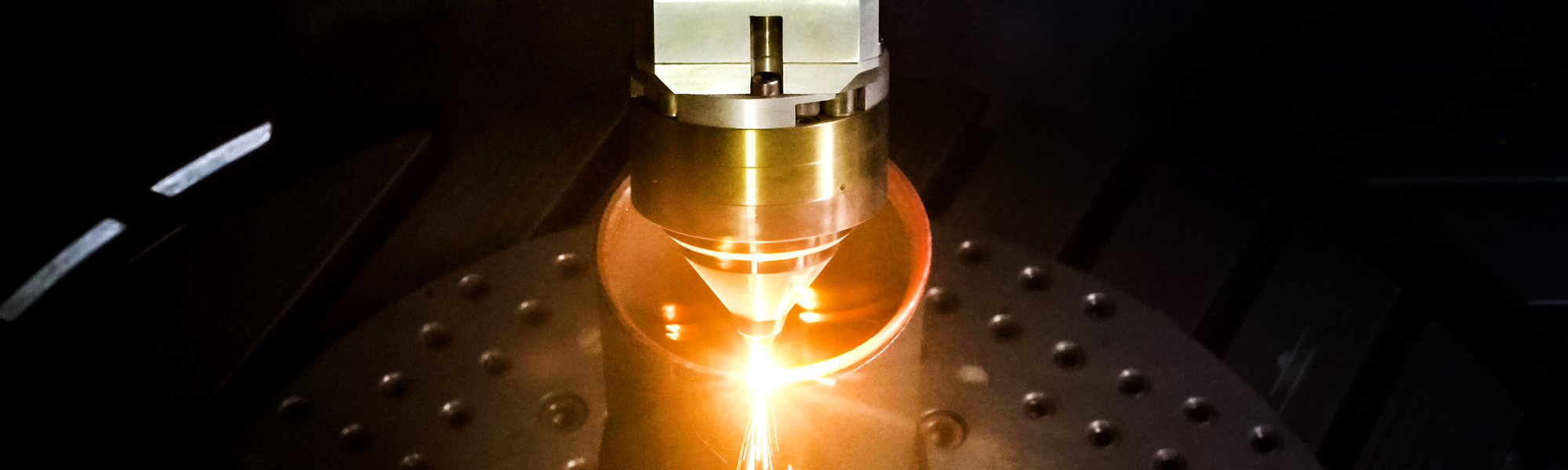

3DM – DED(Direct Energy Deposition)

M3 Partners' DED equipment is DMG MORI's hybrid equipment, which can perform Metal 3D printing and 5-axis CNC machining at the same time in one equipment, making it possible to realize the dimensional precision of DED-type laminates at the level of CNC machined parts. In addition, a natural interface is formed at the same time by using two types of materials in a desired ratio, and through special laminating process, products with various special shapes are produced on the same surface. DED manufacturing is now widely adopted in press mold, challenging parts for aerospace, automotive and power plant turbines etc.

DED Material

SUS316L, Inconel 625, 718, FERRO55, SS400, STELLITE 6, 21, Cu10Al, HSS M2

Flatform size

최대 Ø 500 mm

Finish

Heat treatment, Sanding

Equipment

| Equipment | Manufacturer | Model | Work Bed(mm) | Q'ty | ||

|---|---|---|---|---|---|---|

| X | Y | Z | ||||

DMLS |

EOS |

M290 |

250 |

250 |

325 |

3 |

DED HYBRID |

DMG MORI |

LASERTEC 65 3D |

735 |

650 |

560 |

1 |

M3 PARTNERS

Metal 3D Printing PORTFOLIO