Why M3 PARTNERS?

Fast lead time for 3D printing and finish.

Same-day quotation with competitive price.

Collaboration of 3D printing and CNC machining in-house.

Silicone over-mold and vacuum casting is applicable.

Cost-effective appearance model level finish options: polishing, color spray and more.

Three options of materials: ABS for general purpose with smooth surface and assembly fit, Acrylic for translucent application, Nylon for stiff and strong structures.

DFM suggestions and communication skills with overseas customers around the world: USA, Canada, UK, EU countries.

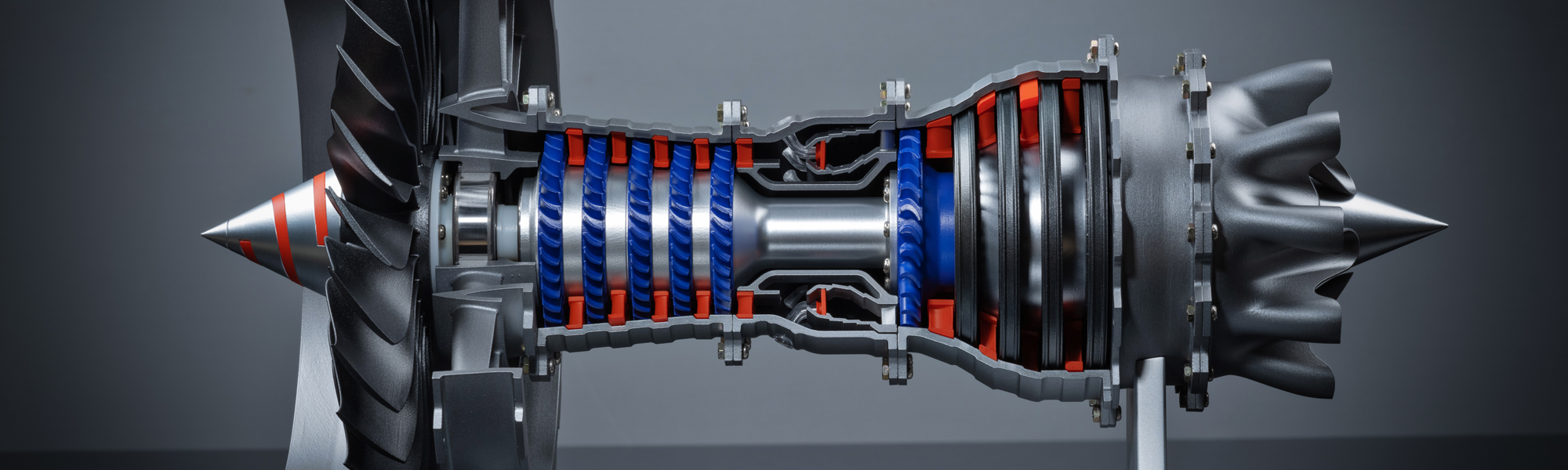

3DP – SLA(Stereo Lithography Apparatus)

SLA 3D printing is a type of additive manufacturing technology that uses a laser to cure liquid resin into solid structures. We provide acrylic material for high-quality post processing such as polishing and coating and ABS material for stronger structure with more accurate dimensional tolerance and lower surface roughness, which is useful for prototype and complex assembly parts in short lead time and less expensive cost.

Since M3 Partners is equipped with many industrial level SLA 3D printers,

we can provide fast lead time for complex geometry parts with lower price than conventional process.

SLA Materials

ABS(natural ivory opaque) & Acrylic(natural translucent)

Platform size

560 x 560 x 360 mm

Finish

Sand Blasting, Coloring(ABS), Transparency(Acrylic)

3DP – SLS(Selective Laser Sintering)

SLS 3D printing is an additive manufacturing technology that uses a laser to sinter powdered Nylon material to create a solid structure

for not only prototyping but also actual functional parts.

It doens’t need support structure because the powder filled in the platform can support the structure during sintering process, which enhances freedom of internal design and has advantage of making assembly part without splitting it into several subparts.

SLA Material

PA2200

Platform size

340 x 340 x 540 mm

Differentiation

Equipped with 3D printers and CNC machines, spray & painting finish units available in-house.

3D printing operators and polishing experts experienced with mock-up appearance model finish.

CNC machining and 3D printing applied to the project at the same time to achieve high quality and cost effectiveness.

Equipment

| Equipment | Manufacturer | Model | Work Bed(mm) | Q'ty | ||

|---|---|---|---|---|---|---|

| X | Y | Z | ||||

|

SLA |

UNION TECH |

LITE600 |

560 |

560 |

365 |

4 |

|

MAGFORMS |

Dargood 600 |

560 |

560 |

360 |

2 |

|

|

SLS |

EOS |

P396 |

340 |

340 |

530 |

1 |

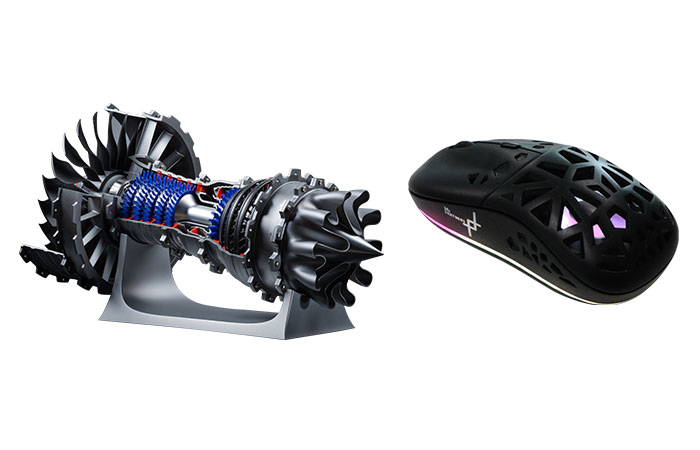

M3 PARTNERS

Plastic 3D Printing PORTFOLIO