Why M3 PARTNERS?

Quick-Turn Tooling

Post-Operations

Core Capabilities

Reliable Quality

Injection Molding Processes

Medical Injection Molding

Class 8 cleanroom molding PPAP and IQ, OQ, PQ validation

Overmolding

Overmolding, Insert molding and 2-shot molding with Plastic, Silicone and Metal

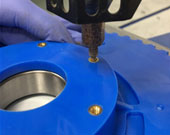

Insert Molding

Molded-in Threaded inserts

Injection Molding Materials

Medical Grade Materials

Color compounding available for generic and medical materials

Prototype to Production Tooling

| Description | Engineering Samples | Pilot Samples | Pre-Production | Mass Production |

|---|---|---|---|---|

|

Mold Material |

Aluminum |

P20 |

NAK80 |

STAVAX |

|

Moldbase |

Standard |

Standard |

Standard |

Custom |

|

Guaranteed Shots |

1K~5K |

10K~30K |

50K~100K |

1M |

|

Tooling Actions |

Mechanical Slide, Manual Lifter |

Mechanical Slide, Lifter, Auto-Degating & Ejecting |

Mechanical Slide, Lifter, Auto-Degating & Ejecting |

Mechanical angular slide, lifter, Collapsible Core, Auto-Degating & Ejecting |

|

Mold Flow |

Mold Flow Advisor |

Moldex |

Moldex |

Moldex |

|

T0 Lead-Time |

6 days |

6~7 days |

8~10 days |

15~25 days |

|

Presses (t) |

15~450 |

|||

|

Min. Part Size |

0.02g |

|||

|

Max. Part Size |

335X194.50X180mm |

|||

Schedule_T1 100ea

| 100ea | Rapid Tooling-Time Table(Working days) | |||||||

|---|---|---|---|---|---|---|---|---|

|

Process |

D+0 |

D+1 |

D+2 |

D+3 |

D+4 |

D+5 |

D+6 |

Note |

|

Data Release |

|

|

|

|

|

|

|

|

|

Quote/DFM 1 |

|

|

|

|

|

|

|

|

|

PO |

|

|

|

|

|

|

|

|

|

DFM2 |

|

|

|

|

|

|

|

|

|

Tool Design |

|

|

|

|

|

|

|

|

|

Tool Build |

|

|

|

|

|

|

|

|

|

First Article Sample Try |

|

|

|

|

|

|

|

|

|

QC |

|

|

|

|

|

|

|

|

|

Shipping |

|

|

|

|

|

|

|

|

Post Processing

Typical L/T:2~3 days

SPI-A1~D3

VDI and Mold-Tech texture

Painting and Soft Touch Coating

Pad printing, Silk Screening

UV coating, EMI coating

NCVM

Heat Staking, Ultrasonic welding

Sub-Assembly

Speedometer

Laser Engraving

Painting

UV Coating

NCVM Coating

Pad Printing

Ultrasonic Welding

Staking

Validation Process

Installation Qualification Standards

| Content | Standards | Report | Dep't |

|---|---|---|---|

|

Mold Measuring |

Drawing |

Mold Inspection Report |

QC |

|

Mold Performance |

2hr/ No Problem |

Mold Check Sheet |

Mold |

|

Cosmetic |

|||

|

Injection Equipment Performance |

2hr/Manual |

Maintenance Management Report |

Production |

|

Injection Machine Check Report |

Qperational Qualification Standards

| List | Standards | Report | Dep't | Frequency |

|---|---|---|---|---|

|

Low Run |

300 Shot or More then 2 hours |

Injection Control Sheet |

Production |

1Run |

|

High Run |

||||

|

Nominal Run |

||||

|

Cosmetic Inspection |

G-║/AQL=0.65 |

FAI Report |

QC |

1Run |

|

Measuring Inspection |

Measuring Sample n=10 |

FAI Report |

||

|

Review the Results |

- |

Corrective Action Report |

Technical Sales |

- |

|

Limit approval |

- |

Limit Approval Report |

Performance Qualification Standards

| List | Standards | Record | Department | Frequency |

|---|---|---|---|---|

|

Optimal Injection Conditions |

1,000 shot or More than 4 hours |

Injection Control Sheet |

Production |

3 Runs |

|

Cpk |

≥1.33 / n=30 |

Cpk report |

QC |

3 Runs |

|

Cosmetic Inspection |

G-║/AQL=0.65 |

Inspection Report |

||

|

Measuring Inspection |

n=10 |

Inspection Report |

||

|

Review the Results |

- |

Corrective Action Report |

Technical Sales |

- |

|

Limit Approval |

- |

Limit Approval Report |

M3 PARTNERS

Injection Molding Portfolio