DMLS Cooling Technology Overview

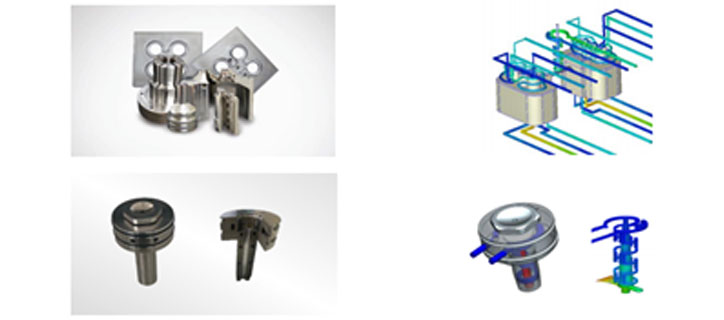

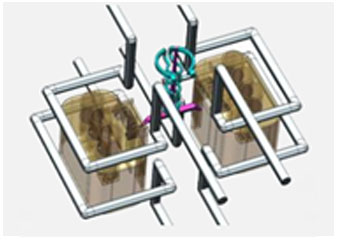

What is DMLS Conformal Cooling?

The DMLS cooling system is our differentiating technology which utilizes metal 3D printing technology to create molds that require cooling or uniform temperature control, part cooling in a straight line or curve to suit your needs.

Channels are designed and built to optimize cooling efficiency, allowing you to lncrease productivity, reduce costs and defects.

Direct Meral Laser Sintering shape-adaptive cooling system

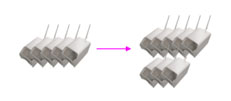

Conventional Cooling Methods

Limited cooling with X, Y, and Z in a straight-line drilling

DMLS Cooling Methods

Internal cooling with freeform, three-dimensional curves based on product geometry

Benefits and differentiators

of DMLS Cooling

Benefits and differentiators

Cooling cyde time: 20 -60% reduction

Molding defect rate: 10% or more reduction

Minimize deformation and hot spots: 10% + improvement

Excellent hardness: HRC 40 to 57

High durability and strength : 500K shots

Achieve uniform quality with uniform temperature control

Should i apply DMLS Cooling

For molds with short part cyde times and long runner solidification times.

You want to achieve stable and uniform part quality.

Reducing process costs, improving part cost competitiveness.

Increased productivity

reduces energy costs and carbon

Reduced defect rates

reduced scrap and enviromental pollution

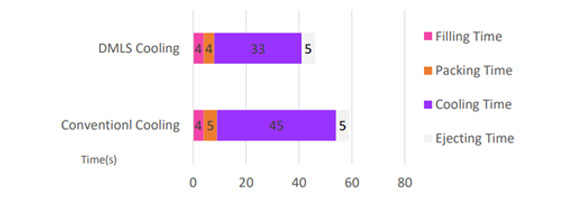

22% reduction in overall cycle time (-13s)

cooling time occupancy of about 70% or more

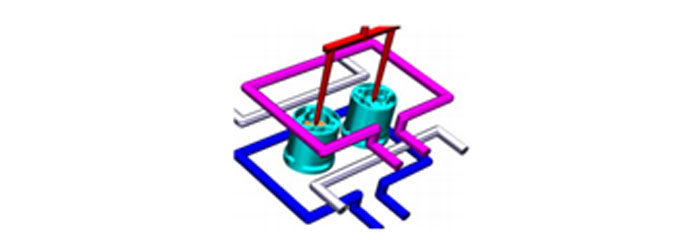

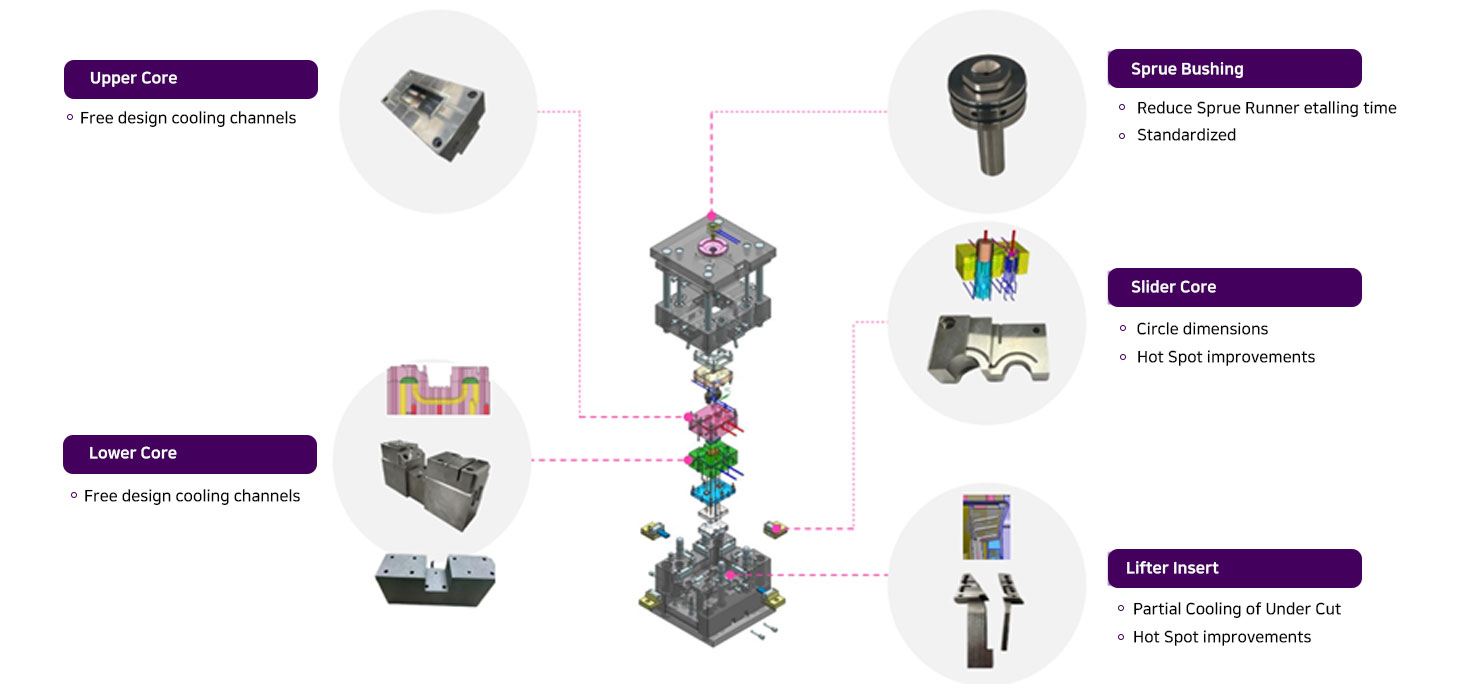

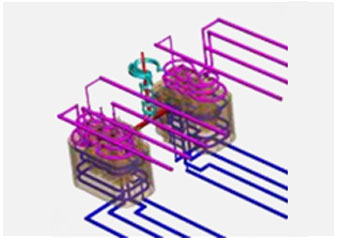

DMLS Cold Runner Mold Solution

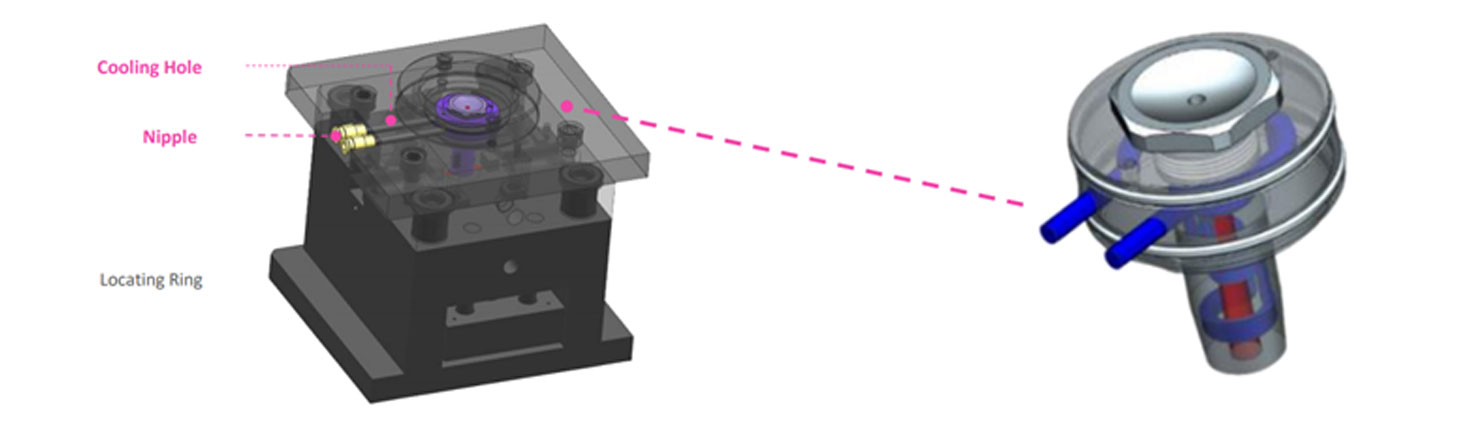

DMLS Sqrue Bushing Solution

STRENGTH

Reduce molding cycles

- Reduce costs by increasing productivity

Stable quality

- Stable temperature control

Defect rate reduction

- Avoid bad string and runner cracks

FEATURES(DESCRIPTION)

Material: MS1 (similar to SKA61)

- Maraging Steel

Hardness: HRC50

- HRC45 to 57 available

Warranty: 1 year free replacement

- Clogged cooling holes

DMLS SPRUE BUSHING

is a metal 3D additive menufacturing technology that uses an all-in-one single component.

When the plastic resin is shot into the part, heat generated in the injection entrance in much more evenly distributed across the surface, and the sprue runners cool quickly.

Direct Metal Laser Sintered Conformal Cooling Channels

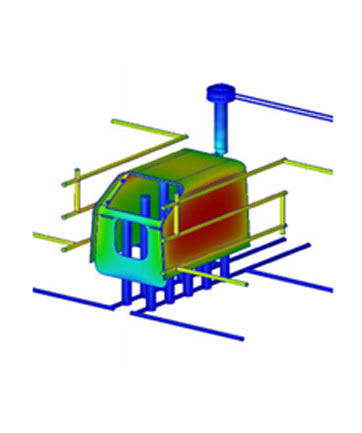

Hybrid Tooling Case Study

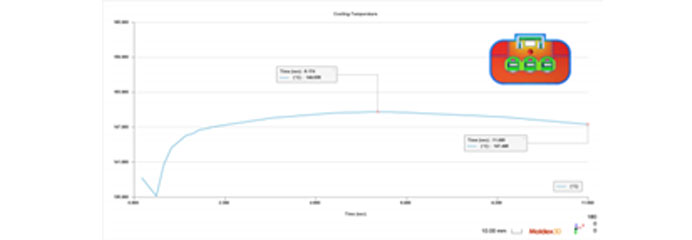

Total Cycle Time Reduction

- No Cooling: 59s/Cooling Time: 455

- DMLS: 46s(22% Reduction) /

Cooling Time 335(27% Reduction)

- No Cooling: $50K / DMLS: $33K

Reduction of Defects

- No Cooling: 3.2% / DMLS: 1.4%

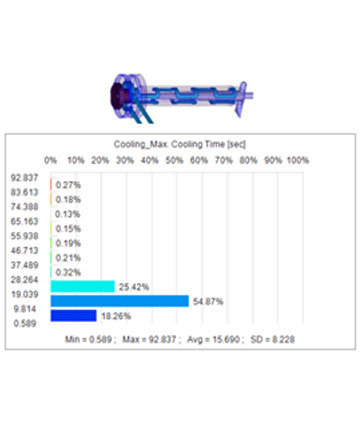

Comparison by Sprue Runner Cooling Time

| Time | 10s | 20s | 30s | 40s |

|---|---|---|---|---|

DMLS Cooling |

|

|

|

|

No Cooling |

|

|

|

|

DMLS Nozzle Sprue Bushing

DMLS Nozzle Sprue Bushing Overview

& Characteristics

Cost Analysis Comparison

Estimation References: 280Ton (labor rate $25/hr/100K production standard)

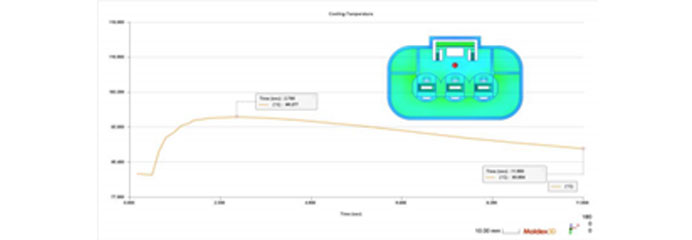

This is an example of verifying the Sprue Runner solidification cooling time.

The overall molding cycle time may vary depending on working conditions, part size, appearance and dimensional accracy, and core cooling structure.

Information

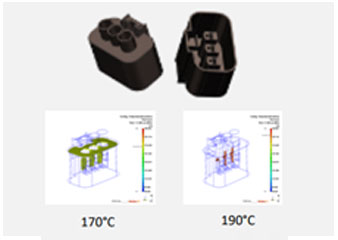

Product Name: Front Housing

Resin: PC White

Cavity: 1 x 1

Weight: 268g

Avg. Thickness: 2.2mm

Sprue Runner Weight: 6.3g

System: N Sprue Bushing Conformal Colling

Application: Medical Device Enclosure

DMLS Cold Runner Case Study

Conventional Cooling Methods

Cycle time: 24.6s

DMLS Cooling Methods

Cycle time: 24.6s